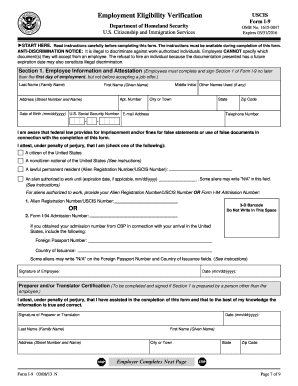

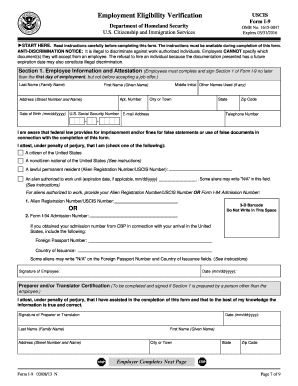

Who needs a form HHS-690?

Organizations that apply for a federal grant, need form HHS-690 to be on file with the Department of Health and Human Services. It is enlisted as the first document to submit with an original application on the HHS checklist (form 5161-1).

What is form HHS-690 for?

Form HHS-690 stands for Assurance of Compliance. There used to be 4 separate forms to assure applicant’s compliance with Civil Rights Act (1964), Rehabilitation Act (1973), Education Amendments (1972), and the Age Discrimination Act (1975). Now they are all united under form HHS-690.

Is it accompanied by other forms?

Applying for a federal grant is a complicated multi-stage process. It involves a number of federal institutions. To make sure you’ve gathered all the requested forms, you can check out the list on the HHS form 5161-1.

When is form HHS-690 due?

The due date is the same as the due date for a federal grant application.

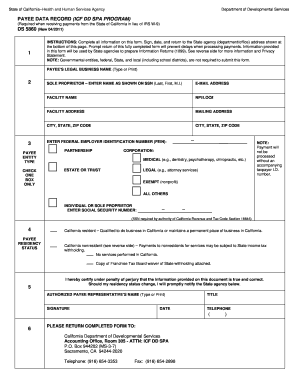

How do I fill out a form HHS-690?

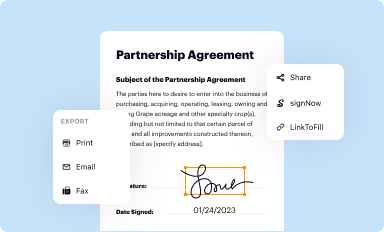

There is only one sheet to fill out. You must read every paragraph carefully. It is a legally binding assurance that all the documents and your further activity during the project are and will be in compliance with the legal acts, listed on this form. When you are ready to put signature and date, you must also type your name and position you hold in the applying organization. Also, you should type name of healthcare facility receiving/requesting funding and its address.

Where do I send it?

The mailing address is:

U.S. Department of Health and Human Services

Office for Civil Rights

200 Independence Ave., S.W.

Washington, D.C. 20201